Company Profile

EST It operates in the fields of cleaning the surfaces of metal parts such as aluminum, steel, stainless steel and brass, coating with chemical processes, painting with wet paints and cerakot, marking and protecting them with dry film lubricants. It manufactures in an area of 2500 m2 in the İvedik Organize Sanayii region with facility security assurance. Company mission is continuous increase of knowledge and ability, meeting customer requirements and expectations, and increasing the customer satisfaction. Vision of EST Surface Treatment is to be an international brand in its line of business. Coating and paint services, we provide are towards corrosion resistance, wear resistance, adhesion durability, adding slickness, decreasing friction coefficient, surface hardening, adding electrical conductivity/resistivity which can be over aluminum, steel, stainless steel, titanium, brass, copper, chrome nickel and magnesium alloy surfaces, and/or customer-based processes which carries aesthetical features

Our Expertise

Beginning from year 2007, EST became the first operator of “Anti Friction Coating” and Dry Film Lubricant products of “Technocoat®” brand. EST added the other chemical treatments supporting this application from year 2010 and continued its operations for decreasing metal loss, protecting metals and adding functional and aesthetical features while meeting the needs of Aerospace industry. Company carries the NADCAP certification and other ISO documents which meets the quality requirements of the Aerospace industries. EST also offer services to Machine Manufacturing, Automotive, Medical, Electricity Industries and Communication Industry besides

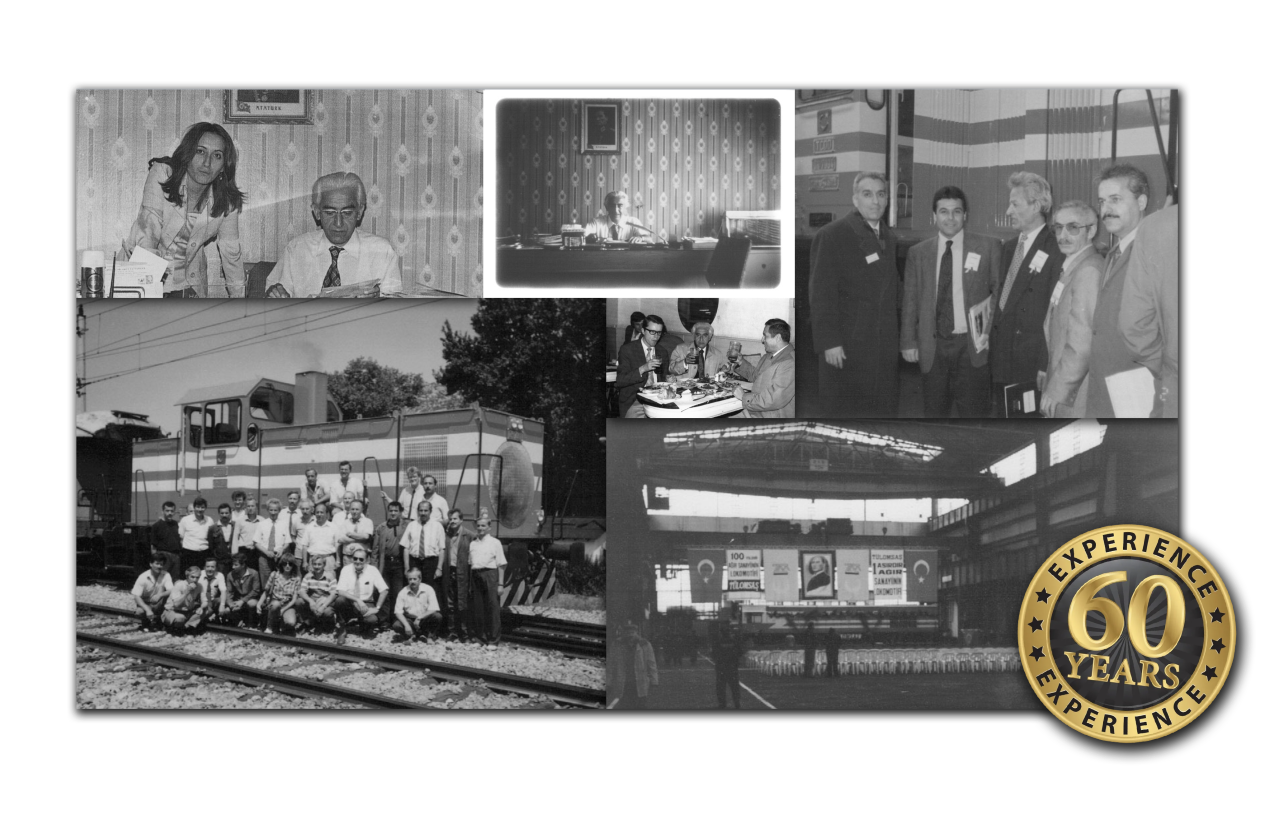

EST (Endüstri Teknik Surface Treatments) is a subsidiary of a family-owned engineering firm, founded in 1961. For the past 20 years, under the leadership of its third generation, our firm has been providing a wide array of solutions to numerous private and quasi-governmental clients in the defense, aviation, marine-tech, electric vehicle and space industries.

EST (Endüstri Teknik Surface Treatments) is a subsidiary of a family-owned engineering firm, founded in 1961. For the past 20 years, under the leadership of its third generation, our firm has been providing a wide array of solutions to numerous private and quasi-governmental clients in the defense, aviation, marine-tech, electric vehicle and space industries.

Our History

In 2006, EST has started to offer services to coating industry with Dry Film Lubricant applications. “Anti-Friction Coating” and other applications regarding different needs of Molykote brand started to be applied in our facilities. These applications are supported by technical data sheets of the products and overseas workshops. One expert, two operators, and one assistant personnel was working in 2006.

In 2007, long term agreements were made with Dry Film Lubricant customers. Potential customers were targeted by Endustri Teknik personnel and supported by workshops, demonstrations and visual aids. One expert, three operators, and two assistant personnel was working in 2007.

In 2008, appropriate surface preparation requirements have arisen, therefore sanding machine setup and phosphate coating tanks are installed in the facility. The number of personnel reached 10. Wet paint activities started that year.

In 2009, quality improvements are made and certified by the ISO 9001 Quality Management System. Hook conveyor system installed to ground floor, belt conveyor system to the second floor in addition to the Coating facility which is located at the ground floor.

In 2010, conveyor systems became active. Mass applications are started for automotive, machine manufacturing and piston manufacturers in the area of Dry Film Lubricant and Wet Paint processes. Alodine Chromate Conversion and Passivation coating operations started. Trademark registration completed for “TECHNOCOAT” Dry Film Lubricant applications. The number of total chemical processes reached six that year. Laboratory installation is completed to calculate/measure coating quality performances. Salt Test equipment purchased and measurements for corrosion abilities of the coatings started. Aselsan decided to work with Endustri Teknik in the area of Dry Film Lubricant coating and made a joint procedure study. This procedure made these products to be used in many new designs possible. In this way operating with Defense Industry started. In the same year, EST got approval of quality from Roketsan and started to work with MKEK.

In 2011, the number of processes increased to eight by adding Anodizing and Hard Anodizing Chemical processes. The number of coating customers increased with these additional processes. Started working with customers such as Samsun Yurt Savunma, Girsan, Yaltes, Proted. EST got an approval of quality from FNSS.

In 2012, EST got approval for seven chemical processes from Aselsan. Started working with Aselsan and its sub-industries. Practices started for Aerospace Industry. Contacted with companies such as TAI, ALP, KALE, FCMP, COŞKUNÖZ and announced investment decisions for Aerospace Industry. Companies advised Endustri Teknik on getting NADCAP certification. Applied for NADCAP and inspection towards Quality and Chemical processes were done in November. The number of process increased to nine by adding the Chromic Acid Anodizing line.

In 2013, the Certification of NADCAP is completed. EST got the “EATON” and “FAI” approvals for Alodine, Sulphuric Acid Anodizing, and Hard Anodizing. Started working with FCMP, as the main company EATON. Continued to contact with other customers. EST got a Wet Paint approval from Aselsan.

In 2014, EST got approval for an additional 14 chemical processes from Aselsan. Zinc line installation was set up in October. Intense studies have done towards Occupational Health and Safety, all the equipment in the facility optimized towards OHS, fire and explosion risks minimized and all necessary precautions were taken. The customer portfolio is expanded with all these efforts towards OHS.

In 2015, EST got approval for the Zinc Plating line from Aselsan. With this approval, our approved chemical process number reached to 15. The number of the approved processes is 16 including the wet paint. In September, EST got approval for five chemical processes from Roketsan. In November, an aluminium chromate coating line with 2 tons of volume is installed. On 16.10.2015 coating and painting operations parted from the main company and continued as EST Endüstri Teknik. EST Endüstri Teknik web site started to publish under www.estendustriteknik.com. We thank everyone and top management who have participated in our activities.

In 2016, the company continued operations of coating and painting under EST Endustri Teknik, physical advancements are made to improve the work environment. EST took a step towards an increase in its operations by taking the ownership of the building number 21. The company attended 3. ICDDA activities to increase operations on Aerospace Industry and made new contacts from the industry. Production capacity increased by 35% with 28 personnel.

In 2017, activities increased by around 85% with the start of new projects in the Aerospace Industry. The number of customers reached 250 and the number of workers reached 40. With the increased workload in performance tests on coating applications, “Chemistry Laboratory” installation set up in 70m2 of area to increase quality. Abrasion Resistance Tests in the new laboratory begun with the purchase of Abrasion Test equipment. Personnel occupational health and safety conditions are improved by the installation of appropriate ventilation, lightning and “Masking Area” of 50m2. EST Endustri Teknik got Skorsky subcontractor approval with Aydın Yazılım company in May 2017. The company got inspected by 19 processes under Aselsan and completed successfully in August. NADCAP inspection period time has increased from 18 months to 24 months with the inspection which took place in October. Information on Coating and Surface Treatments is given to young engineer candidates at Surface Treatment Symposium at Kırıkkale University. We thank everyone and top management who have participated in our activities.

Capacity increase initiative has started and technological investments are made with the incentive taken from KOSGEB’s (Small and Medium Enterprises Development Organization of Turkey) Kobigel SME Development Support Program. 59% of the production increase is achieved with the increase of processes and clients. Precious metal coatings such as Gold and Silver for metals like Aluminium, Brass, and Copper started, quality control of surfaces for these coatings is performed with 10x microscopes. Adjacent building (Number 23) is bought and required actions are taken to increase production. At the end of 2018, the required actions for production are finished with both machinery purchases and construction works.

50% capacity increase is achieved with new hard anodizing and chromatizing lines. Paint capacity is increased by 50% with the latest wet paint cabin. Marking/Etching service has started with the purchase of the Laser Engraving Machine. By the end of 2018, number of customers have reached 400 and our personnel reached 50. Canias ERP software is bought and required training are given. EST Endüstri Teknik continues its operation with its 22 processes.

With the completion of construction works at the end of 2018, EST Endüstri Teknik has continued its successful operation with a 3000 meter square of Coating and Painting services. Cerakote coating service, which didn’t have much demand in previous years, has nearly reached 15% of the total production. EST Endüstri Teknik also got approvals regarding the Gold and Copper plating processes in March. With the gold plating services, 5% of the production increase is reached for the total revenue. To export our services and to follow the latest trends, EST Endüstri Teknik attended Famex 2019 in Mexico and 2019 Paris Air Show with the support of OSSA. EST Endüstrik Teknik also attended domestic expos such as IDEF and SANTEK. EST Endüstri Teknik passed the NADCAP Certification audit without any problems and retained its merit status in November. In December 2019, AS9100 and Facility Security audits took place, documentation processes for these audits are still ongoing. Adaptation processes on Offer-order, accounting, purchasing and material in & out modules for Canias ERP implemented, production module activation is scheduled for 2020. At the end of the year, production support obtained from the government (EYDEP).

“In March 2020, we were entitled to receive AS9100 certification from the Breau Veritas certification body, and we continued to serve our customers with higher quality. In June, we succeeded in securing our personnel, customers and customer property more by obtaining the “National and NATO Facility Security” certification from the Ministry of National Defense. The fairs and conference organizations we planned in our country and abroad were postponed to a year later due to the Pandemic. For this reason, our communication with our customers continued with online calls. While combating the epidemic, our responsibilities on Occupational Health and Environmental Safety have increased, and urgent actions have been taken in our facility on hygiene measures, virus protection and ventilation. In the spring and summer months, our production intensity decreased by 30% due to the decrease in the jobs of Defense and other industries. In this period, we tried to make the maximum contribution to the fight against the epidemic by making surface coatings of respiratory devices produced by ASELSAN.

In November, we were able to obtain an Approved Supplier Certificate from the General Directorate of Military Factories of the Ministry of National Defense. We had to postpone the Canias production module due to a limited year of face-to-face training. At the end of the year, we were entitled to state support from the Kobigel-Kobi development support program from Kosgep for strengthening the technological infrastructure by integrating automation in production. “

Our Mission

Aerospace Industry, superior service understanding and experience gained by combining high technology to provide excellent, reliable, high quality and services that will make a difference.

Our Vision

To become a world brand with the product and service quality that we will give based on honesty and trust beyond the expectations of our customers.